Optimize Your Resources

Improve Your Manufacturing

Increase Your Profits

Blue Technik personnel will help your organization achieve maximum productivity and efficiency in your manufacturing operations.

- Design equipment layouts and workspaces for improved efficiency.

- Develop Value Stream Maps to identify improvement opportunities

- Review processes and process steps to recommend improvement changes

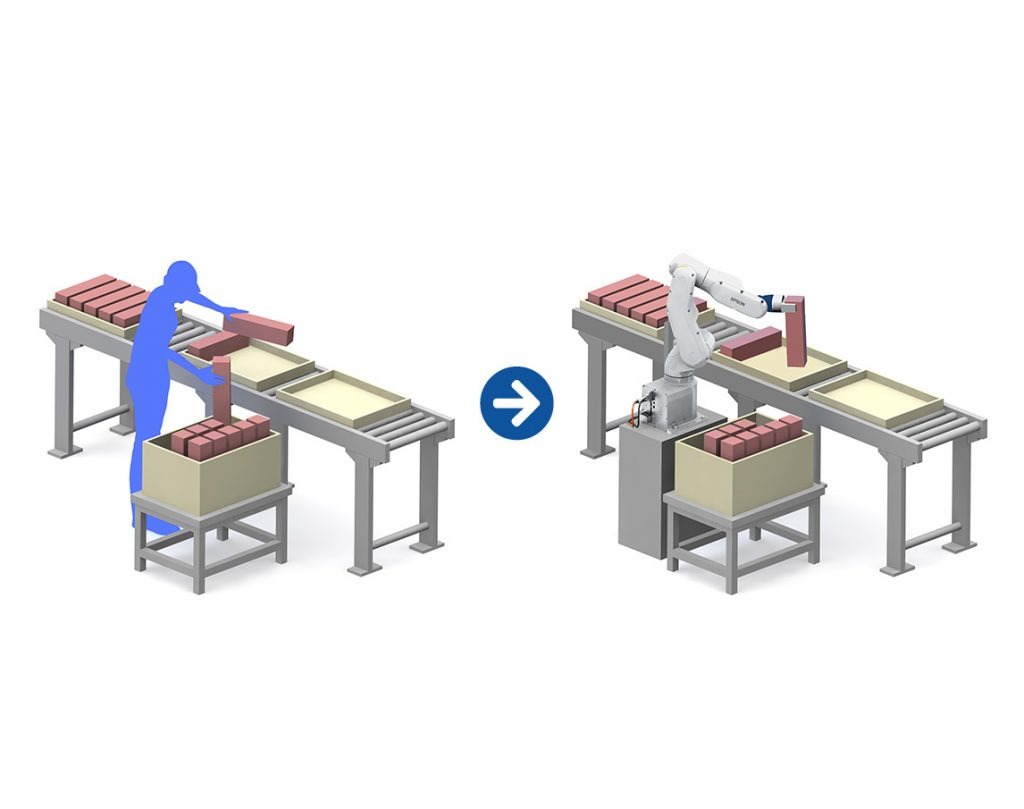

- Recommend new machines or automation for safety, efficiency, and throughput improvements

Image Courtesy of Epson Robotics

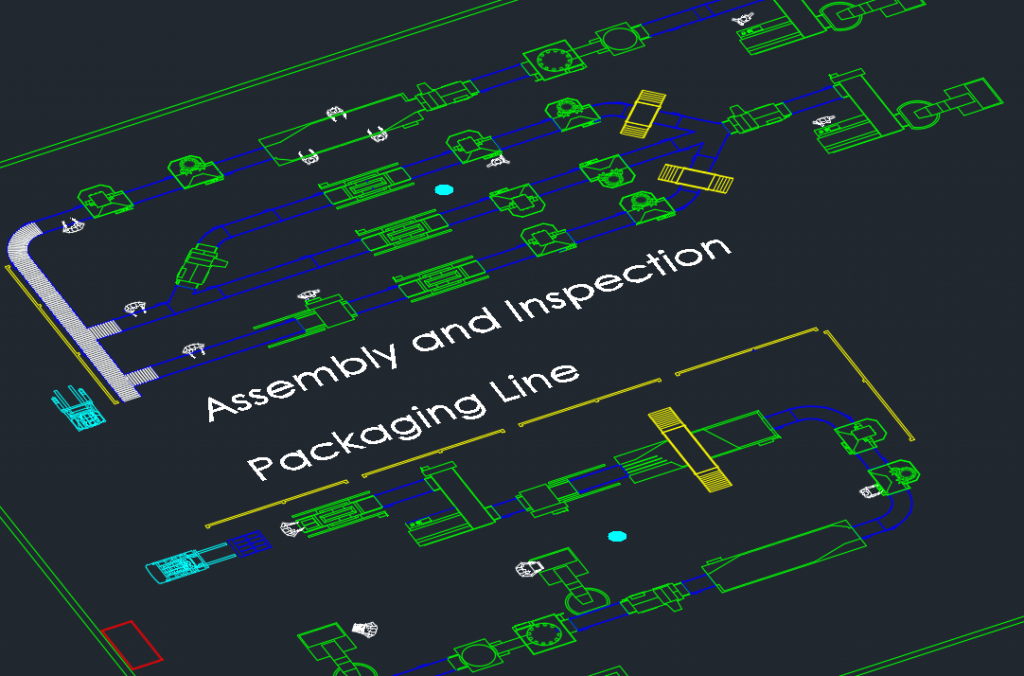

Layout Changes

We will review and analyze your existing work cells to determine opportunities for improvement:

- Floor space reductions

- Improved material flow

- Better storage of tools, equipment, and materials

- Reduced Inventory and Work In Process

- Throughput improvement

Process Mapping & Analysis

Process mapping analyzes the various steps and actions required to produce a product in a work cell.

- Step-by-step sequence review of your manufacturing operations

- Review of cycle times and time standards

- Review of existing Work Instruction documents for accuracy and applicability

- Creation of new Process Sheets, PFMEAs, and Work Instructions

Equipment, Mechanization, & Automation

Many times improvements can be achieved through updates in production equipment, machines, and sometimes effective use of automation. Blue Technik experts can help you develop a plan of action to implement these improvements.

- Improved workstation designs for improved ergonomics

- Material handling recommendations

- Labor content reductions through automation or mechanization

- Cycle time improvements

- Improved process quality with more effective equipment or automation

Image Courtesy CompositesWorld